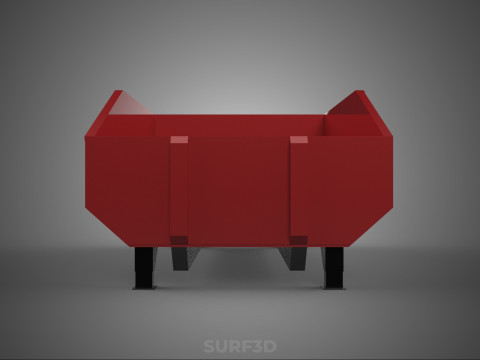

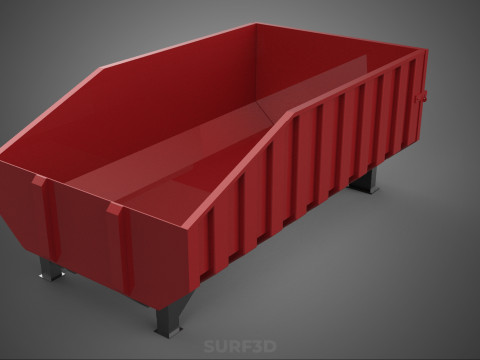

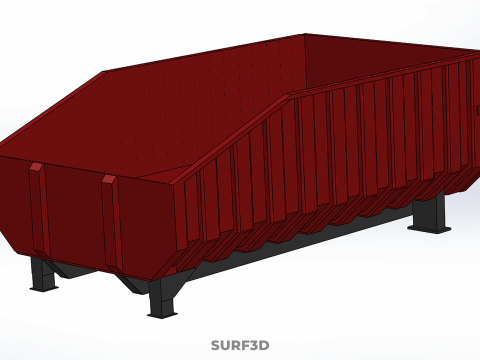

BIN TRUCK BED DUMP BODY BOX CONTAINER CARGO VEHICLE PICK UP CAR Model 3D

- Dostępne formaty: Rhinoceros: 3dm 1.55 MB3DS MAX all ver.: 3ds 100.73 kbBlender: blend 326.86 kbCollada: dae 231.29 kbAutoCAD (native): dwg 394.44 kbAutodesk FBX: fbx 326.66 kbGLB / GLTF: glb 109.90 kbIGES: iges 345.73 kb3DS MAX: max 766.48 kbWavefront OBJ: obj 144.04 kbACIS: sat 190.91 kbSketchUp: skp 300.45 kbSTEP: step 236.04 kbStereolithography: stl 150.53 kb

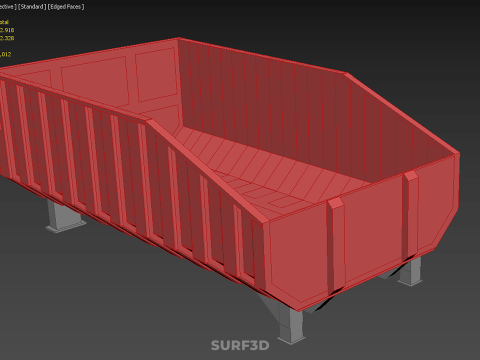

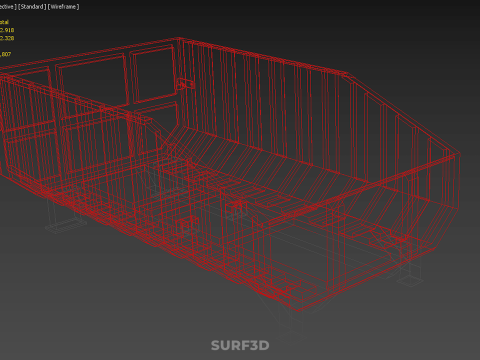

- Wielokąty:12918

- Wierzchołki:12328

- Model animowany:No

- Tekstury:No

- Oparty na szkielecie:No

- Materiał:

- Low-poly:No

- Kolekcja:No

- UVW mapping:No

- Plugins Used:No

- Gotowy do wydruku:No

- 3D Scan:No

- Adult content:No

- PBR:No

- AI Szkolenie:No

- Geometria:Poly NURBS

- Unwrapped UVs:Unknown

- Liczba wyświetleń:293

- Data: 2025-06-19

- ID produktu:580297

- Oceny:

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

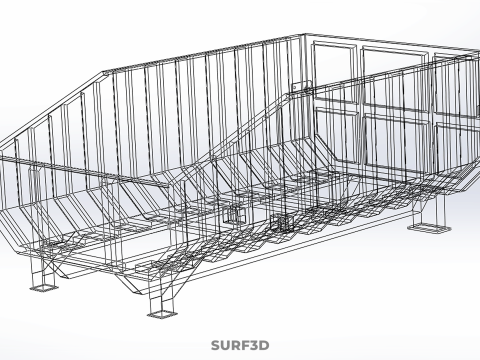

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

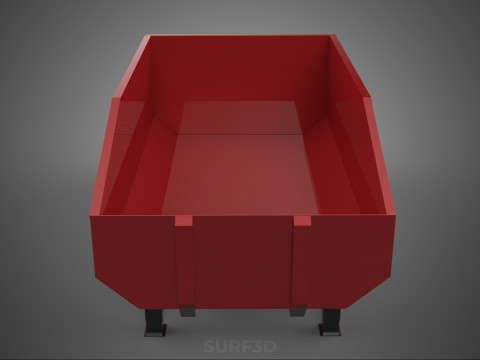

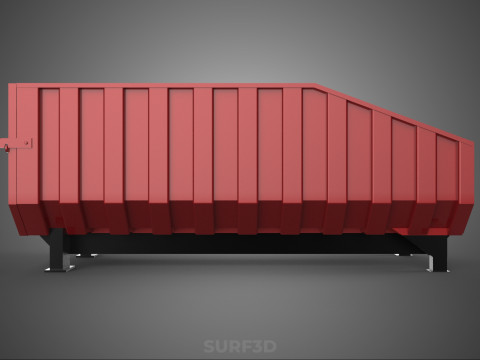

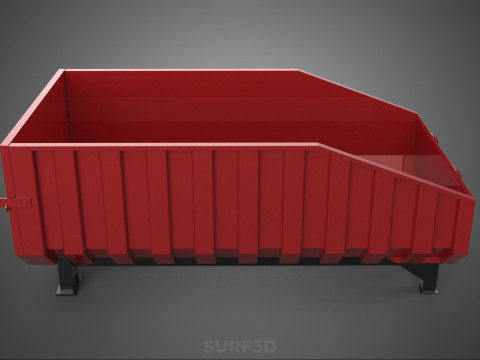

**Light-Duty Dump Body Systems for Pickup Trucks**

A light-duty dump body system for pickup trucks, often referred to as a pickup dump insert, dump bed insert, or dump bed kit, is a specialized attachment or modification designed to convert the standard cargo bed of a pickup truck into a hydraulic dumping mechanism. While sometimes informally associated with "cars," these systems are engineered specifically for light-duty truck vehicles, primarily conventional pickup trucks. Their primary function is to facilitate the efficient unloading of bulk materials such as soil, gravel, sand, mulch, construction debris, waste, and other loose cargo without requiring manual shoveling or tilting the entire truck.

**Purpose and Function**

The fundamental purpose of a pickup truck dump system is to enhance the utility of a standard pickup for tasks involving the transport and deposition of granular or bulk materials. It achieves this by incorporating a self-contained bed or bin unit, typically constructed from steel or aluminum, which fits within or replaces the existing factory bed. This specialized bin is hinged at the rear (usually at the tailgate end) and is connected to a powered lifting mechanism. The most common lifting system is electric-hydraulic, utilizing one or more hydraulic cylinders actuated by an electric pump powered by the truck's 12-volt electrical system (often connected directly to the battery for adequate power). When activated via a wired or wireless remote control, the hydraulic system extends, tilting the front of the dump body upwards. Gravity then causes the material within the body to slide out over the rear tailgate.

**Types and Variations**

The most prevalent design is the "insert" type, which comprises a complete dump body and subframe assembly engineered to slide into and be secured within the dimensions of a standard pickup truck bed. These units are self-contained, carrying their own hydraulic pump, reservoir, and cylinders. Less common, but also existing, are full bed replacement systems where the entire factory bed is removed and replaced with a dedicated dump body and subframe, offering potentially higher capacity or specific features but requiring more extensive modification. Tailgate configurations vary, often featuring a traditional hinged gate that opens from the bottom ('dump style') or a 'double-acting' gate that can either hinge at the bottom for dumping or swing open from the side like a conventional tailgate for standard hauling.

**Components**

Key components of a typical pickup truck dump insert system include:

1. **Dump Body/Bin:** The container structure designed to hold the material.

2. **Subframe:** A supporting structure that fits into the pickup bed and houses the lifting mechanism.

3. **Lifting Mechanism:** Consists of hydraulic cylinder(s), an electric-hydraulic pump, and a fluid reservoir.

4. **Control System:** A wired or wireless remote for activating and controlling the lift function.

5. **Tailgate:** The rear closure of the dump body, designed for controlled release of materials.

6. **Safety Features:** May include safety props or limit switches to prevent accidental lowering or over-extension.

**Materials and Construction**

Dump bodies and subframes are typically constructed from robust materials capable of withstanding heavy loads and abrasive materials. Steel is a common choice for its strength and durability, while aluminum is also used, offering the advantage of lighter weight which can contribute to a higher potential net payload for the truck.

**Applications**

Pickup truck dump systems are widely utilized across various sectors requiring efficient material handling on a smaller scale than conventional large dump trucks. Common applications include:

* **Landscaping:** Transporting and spreading mulch, soil, gravel, and aggregates.

* **Light Construction:** Hauling and dumping building materials, concrete, and debris.

* **Property Maintenance:** Moving brush, leaves, and other yard waste.

* **Municipal Use:** Tasks such as park maintenance, sign installation (carrying gravel/concrete mix), or small-scale public works projects.

* **DIY and Homeowner Use:** Facilitating personal projects involving bulk material transport.

**Advantages**

The primary advantages of using a pickup truck dump system include significant labor savings and increased efficiency in unloading bulk materials compared to manual methods. They add versatility to standard pickup trucks, allowing them to perform tasks typically associated with dedicated dump trucks but at a potentially lower initial cost and with the maneuverability of a pickup.

**Disadvantages and Considerations**

Several factors must be considered when using a pickup truck dump system. The system itself adds weight to the truck, reducing its overall payload capacity by the weight of the insert and its components. The volume of the dump body insert may be less than the original pickup bed volume, depending on the design. The upfront cost can be significant. Proper installation, including a robust electrical connection, is crucial. Overloading the dump body can exceed the truck's Gross Vehicle Weight Rating (GVWR) or Gross Axle Weight Ratings (GAWR), potentially stressing the suspension, frame, and tires and posing a safety hazard. The raised center of gravity when the body is loaded and elevated requires careful operation on uneven terrain.

**Related Technologies**

Pickup truck dump systems are a smaller-scale application of principles found in larger dump trucks, roll-off trucks, and other heavy-duty equipment designed for bulk material transport and self-unloading.

KEYWORDS: Dump bed, pickup truck, dump insert, truck bed, hydraulic lift, material handling, bulk materials, landscaping, construction, debris removal, light-duty truck, vehicle modification, cargo management, utility truck, dumping mechanism, hydraulic system, electric-hydraulic, tailgate, payload capacity, equipment attachment, work truck, residential use, commercial use, property maintenance, gravel, soil, sand, mulch, hauling, unloading, truck accessory.

Gotowy do wydruku: NieJeśli potrzebny Ci plik w innym formacie, zgłoś taką potrzebę przez opcję Support Ticket Konwertujemy produkty na następujące formaty: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Nie konwertujemy scen 3D oraz formaty takie jak .step, .iges, .stp, .sldprt.!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी